- District heating of steel and non-ferrous metal products

- Crank Shaft, Round Bar etc.

Industrial Furnace

- Steel Heating and Heat Treatment Furnace

- Nonferrous Metal Melting and Heat Treatment Furnace

- Ceramic Drying Plant

- Process Line

Local Heating and Heat Treatment Furnace

It is a compact structure that locally heats and heat-treats the required parts of work piece. It can greatly reduce ENERGY and equipment costs. Portable type can be manufactured as required

Application

Specification

Bottom Car Type

It is suitable for heating and heat treatment of Castings, Forgiving and large steel structures. Also It can reduce the scale loss with perfect air pressure control and the amount of product loading and heat treatment as well as waste heat recovery up to 650℃ can even reduce Nox.

Application

- Local heating of steel and non-ferrous metal products

- Crank Shaft, Round Bar etc.

Specification

Roller Hearth Type

It is a facility to transfer and heat the processed work piece by driving the roller in the furnace. It is easy to transfer and automate the stable product, and it can perform uniform temperature distribution and heat treatment of various materials. It is possibie to heat-treat by using protective atmosphere gas.

Application

- Heat treatment of various metal and nonferrous metal products

- Stable product transport by roller drive

- Annealing, Tempering and Normalizing

Specification

Ladle Pre-Heater

It is a facility to preheat the ladle required for steelmaking or AI molten metal bath, and it can be designed and manufactured in various heat sources and shapes. It is uniformly preheated to the bottom with long frame burner installed. It is an eco-friendly facility that can suppress the generation of Co2 by using electic heater in case of small ladle.

Application

- Ladle preheat for molten metal

For steelmaking, AI melting

Specification

Quenching Tank

It is a device that provides rapid cooling of materials heated at high temperature, which can be controlled by using a large amount of Agitating device and it is possible to uniform cooling effect without any distortion of the material.

Application

- Rapid cooling of heated products

Specification

Pit Type

It offers a consistent combination of heating, cooling, cleaning, and tempering, and is suitable for heat treatment of various products such as shafts and gears. In addition, it can be installed in anarrow space using underground pit.

Application

- Carburizing and carburizing (nitriding)

- Annealing and Tempering

- Easy to handle various gears and shafts

Specification

Steel Ingot Heat Treatment Furnace

It is a facility for slow cooling and heat treatment to remove stresses after steel ingot casting. A single Heating Cover can process products of multiple bases and can be equipped with a waste heat recovery burner to achieve high thermal efficiency and eco-friendly heat treatment.

Application

- Stress relieving annealing of medium and large size steel ingots

- For various applications such as slow cooling and preheating

Specification

Aluminum Dissolution

It is a large melting furnace that can dissolve large aluminum lngot and UBC scrap or machining chips. It can be designed and manufactured in various forms such as Tilting Type and Bath Type and used to reduce energy.

Application

- Large ingot and slab melting

Re Cycling (Al Scrap & Machining Chip)

Specification

T-4 Heat Treatment Furnace

It is optimized for T-4 heat treatment of Aluminum and Aluminum Alloy. It can bl rapidly charged and uniformly heated and cooled by strong agitation after heating.

Application

- Processible various AI alloys

- Suitable for handling small and medium-sized parts

Specification

Special Alloy Heat Treatment Furnace

It is a Multi-Purpose type that can perform various types of heat treatment in small quantity production of various kinds of products. Module type, it is possible to operate fully automatically and to carry out heat treatment without oxidation by using the protective atmosphere gas inside the furnace.

Application

- Heat treatment without oxidation, small forging, extrusion molding etc.

- Copper, Copper alloy, Aluminum alloy and Magnesium alloy

Specification

Ceramic Drying Furnace

It is suitable for the treatment of ceramic powders and molded products. It can dry and fuse various types of products by using hot air without deforming or cracking.

Application

- Molding, drying, sintering of ceramic products

- Impeller for molten metal agitation

Specification

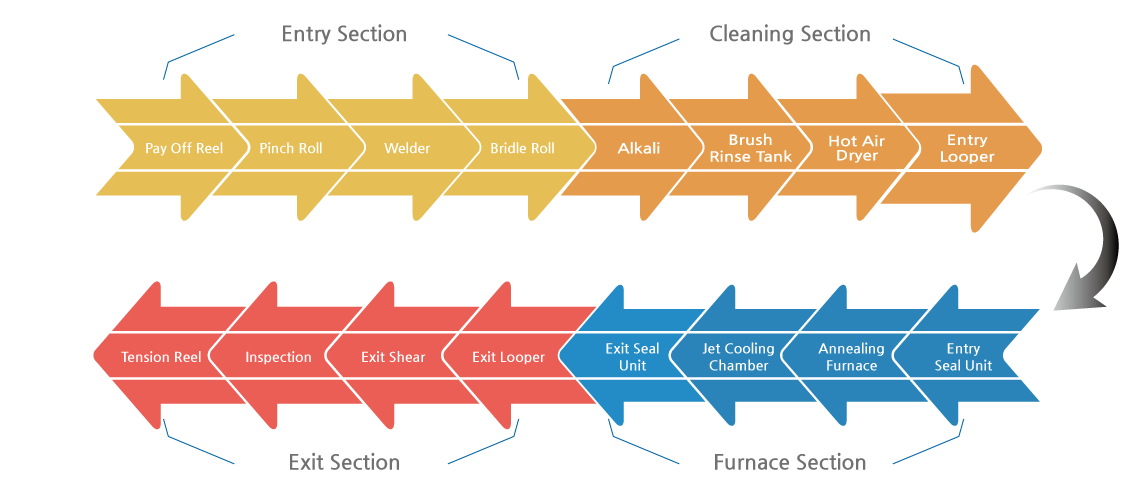

BAL / APL / TAL

It is a continuous heat treatment system for cold-rolled and hot-rolled strip coils. It can efficiently perform heat treatment such as bright annealing, pickling and tension annealing of thin plates and thick plate coils.

Application

- Strength annealing of stainless steel strip coils

- Pickling and heat treatment of Copper Coil

- Rolling stress relief heat treatment of refrigerants and hot rolled steel sheets

Specification

Heat Treatment Process